Gearing up for Harvest

This year is the first one in which every one of our 5.5 acres was transplanted into rice. We have eleven small plots, averaging about a half acre each. Not all of those plots came out perfectly--some had issues with excessive depth or shallowness that led to poor plant performance or weed growth--but on the whole I think it's realistic to expect our largest harvest to date. But it's not over until it's over!

We have acquired a number of new gadgets to help up with harvest this year. This being our seventh season growing rice, we've had various different kinds of specialized machines for a while, but this year I took the step of importing an entire shipping container of used Japanese rice farming machines and tools. Some of them went to work right away for transplanting, and others are just about to be put to work.

The typical machine process for harvesting includes harvesting with a combine harvester, that cuts the crop off of the soil and separates seeds from leaves and stems as it rolls along. Our previous combine harvested into bags, that would fill with 60-80 lbs of rice within a couple of minutes, requiring the operator to stop and put on a new bag. Our new harvester is a little more sophisticated!

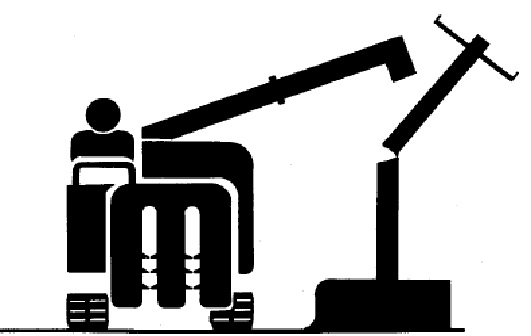

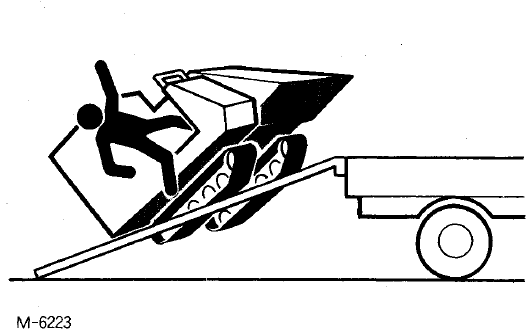

It is an SCP-21, with a fairly modest-sized diesel engine, and it harvests about four feet of width. Arguably its three best features are that it has rubber tracks (meaning that wet fields won't prevent us from getting the harvest in), that it has a grain tank that holds over 1000 lbs of grain (I don't actually know how much exactly) and that it has a built in auger to empty itself into a nearby transport vehicle. It is a 1998 model, yet has only 260 hours of use, meaning that it was used for just a couple of shortish work days each year for almost 20 years. I couldn't get a more recent model due to EPA restrictions, but this one is in incredible condition for its age, and I'm hopeful that we'll be able to use it for many years to come.

Next up is the rice dryer, an Oshima "Royal Temper." As in, "The queen was in a royal temper, " I guess. There is no accounting for the names products are given in Japan, you just have to go with it.

In any event, the Oshima dryer is automated and combines the ability to recirculate the crop with forced air and kerosene-fired heat to expeditiously dry grain. Unlike my wood fired dryer, this one will work through the night. When we bring in the crop the moisture is generally in the 22% range, considerably too high for storage. Expeditious and thorough drying down to a safe level of 14% is pretty critical to quality. And of course the drying arm of the operation has to keep up with the harvesting arm!

Next we have a new huller, which will hopefully solve our brown rice purity problem once and for all. In the past we have struggled to eliminate all unhulled rice seeds from the finished brown rice product we offer for sale. But the Japanese rice hullers have a built-in gravity table specifically to address this issue. So I'm very hopeful, but I won't actually know until we begin using it in earnest.

Learning to use all this stuff being mostly illiterate in the language of their country of origin is a little challenging and I rely on machinery common sense, help from friends, and trial and error. Yesterday Michiko Oishi, capable bilignual person and affiliate of the Vermont Japan-America Society, came by and between us we were able to figure out quite a few labels and functions. And, afterwards, Michiko was able to find an online manual for the combine, which has these helpful suggestions:

Meanwhile, I figured out how to make an ominous beeping alarm turn off on the combine (turns out it was an alert that the throttle is below operating range), and troubleshoot a loud banging noise coming from the dryer (lid was ajar and hitting a moving part).

While all this is going on, the ducks are being fed in the barn and will be available as roasting ducks very shortly. We'll have lots, they'll be going for around $15 each.

Also, the crop is ripening in the field. There is still quite a lot of green down there, so it wouldn't be too surprising if we are starting around the same time of year as last year. We look for about 90% of the rice on the stalks to be brownish in color, and the stalks themselves are usually turning gold as well. Looks like we're still 2-3 weeks out from that all happening.

If this is the case, we'd still be on target to offer up the first new rice by mid-October. I will leave the pre-order system open until at least September 25th. I am also re-applying to attend Burlington Farmers' Market this winter, as I did last year.